DE-STARCHING

De-starching:

Fabrics sold in market, just woven in factories, usually have been starched or have dirt on any place. Wash the white fabric with water for de-starching for better color soak in the later process.

WHITE FABRIC

White Fabric:

After hooking both ends of the fabric on two stretcher bars, fix those bars with strong tension enough to pull the fabric flat in the air.

STRETCH

Stretch:

After hooking both ends of the fabric on two stretcher bars, fix those bars with strong tension enough to pull the fabric flat in the air.

COLORANT

Colorant:

Chemical colorants with the most brilliant color effect and durability are used on items,

Acid-dyestuffs are used for silk and wool and direct dyestuffs for cotton and hemp. The powder colorants are easy to make limitless colors just by mixing them.

COLOR BLENDING

Color Blending:

Put some water in porcelain enamel bowls. Add powered colorants in them and mix well. Make liquid colorants like color inks by heating to dissolve colored powder completely.

PAINT-ON FIRST SIDE

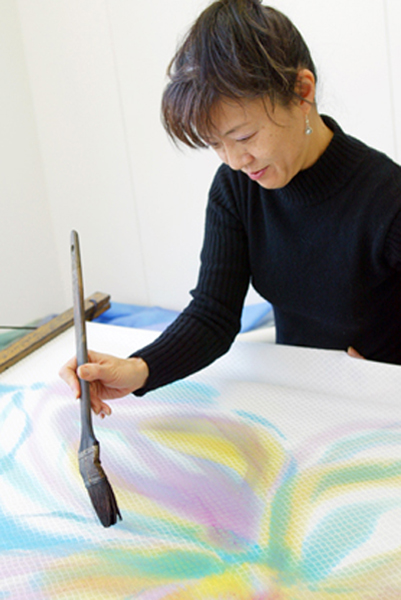

Paint-on first side:

Paint directly on the white fabric with painting brushes. Original techniques are introduced in traditional “hand paint Yuzen”. After checking color running effect on both sides, add painting on the first side and the other alternately.

PAINT-ON THE OTHER SIDE

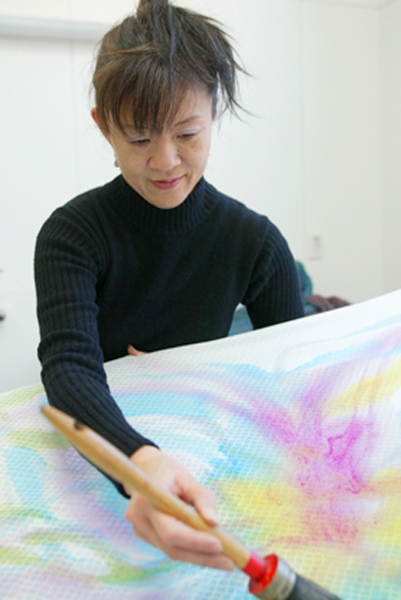

Paint-on the other side:

After paining on the first side, dry it to paint on the other side. Take account the color running from the first side, consider color arrangements for best reversible effect, which must has different images on both sides.

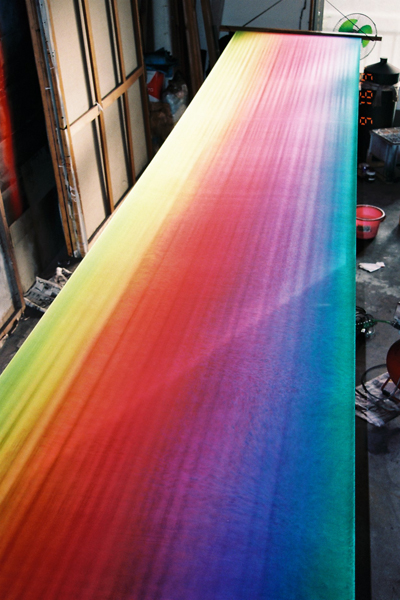

GRADATING

Gradating:

Make unique gradations by delicate adjustment using water and colorants, which are not attainable among printed patterns in markets.

MAKING BLEED

Making bleed:

Various ideas and techniques are used for making color-bleed and overlapping of color dots, such you may seen on Impressionist paintings like Monet’s, which can never created by mass production.

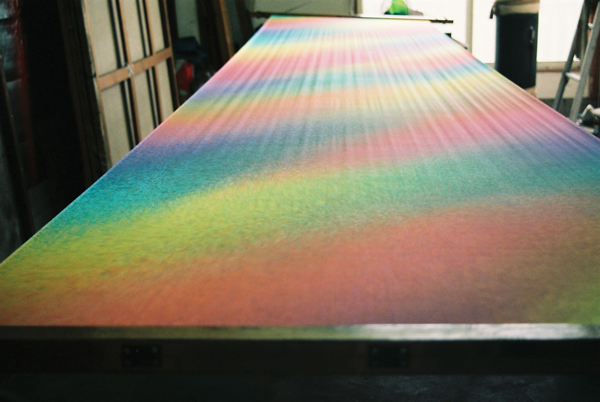

DRYING

Drying:

Changes of color mixture made by GRADATIMG and MAKING BLEED can stop by drying the fabric. In order to fix the colors painted on the fabric, it has to be dried for 3 days until start STEAMING.

ROLLING

Rolling:

Put the painted fabric between a sheet of unwoven fabric with vaporig effect and a sheet of newspaper, not to make any wrinkle. Then roll it thightly.

BOLTING

Bolting:

Spread the painted fabric tight, flat and without any wrinkle between newspapers and sheets of bonded textiles, then bolt it in a tight roll, preventing the dye colors on the fabric from flowing out by direct contact with hot steam.

STEAM

Steam:

Put the rolled fabric in a large specially made copper steamer, and steam it for an hour with maximum heat calories with enough vapor to make colorants and painted colors make firmly stable on the fabric.

WATER WASH

Water wash:

After blowing out vapor on the steamed fabric and wait until it becomes normal temperature, pull out the fabric from bolted roll, and dry it naturally. Remove excess colorants by washing well by water.

CHEMICAL TREATMENT

Chemical treatment:

After washing the fabric well enough to remain no excessive colorants, soak the fabric into chemical solvent which contains both color-fixing stabilizer and softener for smoother feeling to skin.

Re-dry:

Spread the fabric in flat condition and make it dry naturally after completed water wash and chemical treatment.

RE-DRY

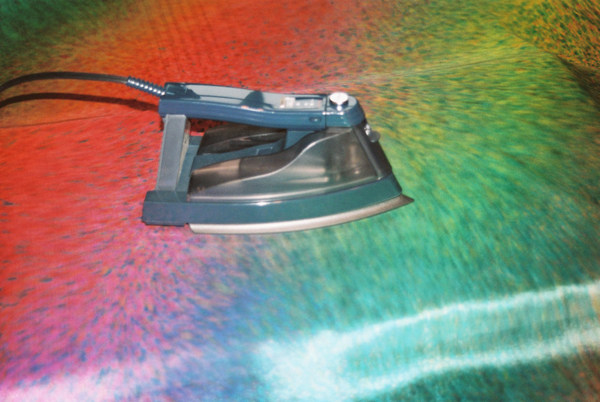

IRON PRESS

Iron press:

For final finishing, use clothes iron on the fabric which painted colors have been fixed and stabilized. When making scarves, trim hems and send to craftsman for hand roll of the hems.

COMPLETION

Completion:

Now kikuko’s sole and original hand-painted item is completed, following through a long process of Japanese traditional hand-painted Yuzen.